The 4 key steps in H2S odour treatment

Collection

Equipment and tanks releasing H2S must be enclosed and covered, and maintained at a small negative pressure to ensure collection of the H2S. Air gaps should be minimized and extraction rates set so that the air velocity through these gaps is of the order of 0.5 m/s. Armatec designs and installs Tank Covers and Hoods to achieve this. Buildings are usually vented to achieve about 5 air changes per hour.

Transfer

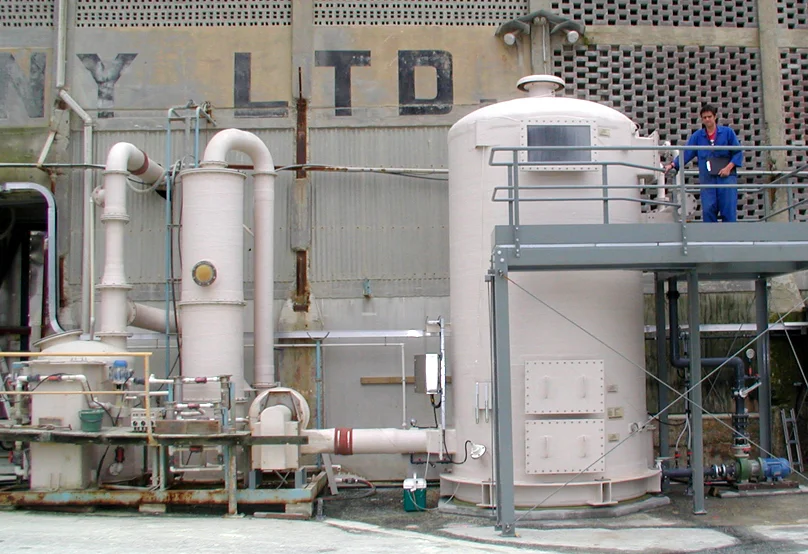

Air containing H2S must then be transferred to the treatment facility via a network of ducting and fans. Armatec designs and installs complete ducting networks including fans in corrosion resistant all fibreglass construction. The H2S is then eliminated in the biological scrubber. A pre-filter ahead of the biological scrubber removes grease and fat, and objects such as plastic bags and other debris.

Air Discharge

The final point where the treated gases will be dispersed must be considered, as air discharged from a biological scrubber has a slight compost like odour (500 to 1,000 odour units). If there are no immediate neighbours, then a well designed stack will provide adequate dispersion so that there are no objectionable odours beyond the boundary. However if there are immediate neighbours, then the air may need to be further treated with a Carbon Bed Adsorber to remove the last of the odours.