Industrial Equipment Reuse - Examples of working towards a circular economy

Reuse is an obvious choice for equipment solutions in a circular economy. Prolonging the life of materials and equipment in service ensures waste is prevented, the use of new materials is reduced and all the associated greenhouse gas emissions for virgin products are avoided. Our team has been actively engaged in exploring reuse as part of our commitment to sustainable business practices, but industrial fibreglass examples have been hard to find.

Searching for information or discussion about FRP industrial equipment & materials reuse provided fewer practical examples than expected. This blog article aims to contribute to the discussion by outlining some of the reuse applications & challenges we have observed, trialed or are aiming for. Armatec has been involved in engineering design and manufacturing using FRP composites for over 40 years, from this position we share our progress and suggest some key considerations for enabling increased reuse of FRP composites materials into the future.

People & Product: Reuse of Armatec industrial equipment has been enabled by the long-life qualities of the industrial fibreglass materials we manufacture with and the design & fabrication skill of our team.

The Opportunity of Reuse:

Considering the types of materials required for different application environments & the inherent repairability of those materials can help identify reuse opportunities.

In over 40 years of operation, Armatec have observed that in many cases of long-life materials, equipment can outlive the user’s business processes. Our primary choice of material has been fibreglass due to its ability to withstand corrosion within harsh operating conditions. The robust design & long-life qualities of the fibreglass materials used, are predisposed to repair, refurbishment, and reuse. We have noted examples of equipment being decommissioned before end of life of the materials. This is particularly important due to the current global challenges for access to recycling solutions for thermoset polymers (which cannot be re-melted like thermoplastics). This is a scenario where reuse of industrial equipment or structural reuse of materials holds a lot of opportunity.

Jelle Joustra, Bas Flipsen, Ruud Balkenende (2021) Explore this opportunity in their paper, Structural reuse of high end composite products: A design case study on wind turbine blades - ScienceDirect outlining the high value of reuse in their introduction:

Prioritising Time to Reuse & Redirect Waste:

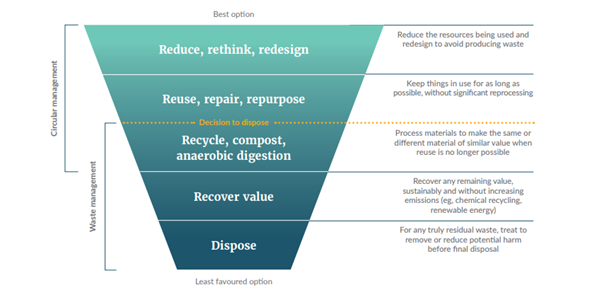

Developing reuse processes & preventing waste at source is a necessary investment for businesses preparing for a circular economy. The waste hierarchy & lean manufacturing processes can help guide decision making & allocating team resource is critical.

As per the waste hierarchy indications, we have focused on reducing waste in concert with our recycling and reuse efforts. Team members are included in developing ideas, conducting waste audits, identifying & implementing improvement ideas. Resulting in successfully diverting recyclables from landfill, swapping single use for reuseable or recyclable consumables and optimising business and manufacturing processes. As we address the 8 wastes of lean manufacturing and encourage lean thinking more opportunities are identified. Engaging with customers to discuss options for reuse has prompted new options for sales & design. It can prove challenging to maintain balance with the internal improvement tasks & time spent on customer jobs. We have found allocating weekly resource to invest effort in these improvements, and supporting with weekly, monthly and yearly events such as team meetings, trainings, consultant visits and audit cycles is helpful in navigating this.

Armatec team members conducting a waste audit. Waste audits provide data & discussion for targeting improvements and celebrating change!

Examples of Reuse of Equipment and Manufacturing Waste:

Reuse of industrial equipment can include a range of opportunities from formal to informal, each presenting their own set of challenges to meet the expectations of receiving clients & users. Direct reuse of equipment, structural reuse of the materials within equipment and reuse of manufacturing offcuts requires different considerations.

Reuse of Industrial Equipment

Reuse via resale has long been occurring in NZ & is now being improved with development of digital platforms such as Civil Share and Mutu or within direct customer relationships. Specialist knowledge of equipment can be required to enable this type of reuse. This is where our Chemical Engineers have found opportunities to support our customers to find reuse options. Below is an example of equipment deployed for a second service life after being repurchased from the first customer. image below).

Service life # 1: Armatec designed, manufactured and installed the air pollution control systems to fit client site.

Service life #2: Armatec repurchased, repurposed & modified to reuse the scrubbing system at 2nd customer site.

Reuse of Materials

Materials reuse (or re-manufacturing) presents a new challenge to ensure the value of materials & manufacturing / construction effort is retained in service before shredding to pieces in any recycling processes (as per the waste hierarchy). For example, decommissioned equipment, where the original structure can no longer function in its designed-for process can be used as components. Our team has identified ways to save time and materials by reusing returned items that could no longer be repaired. Below is an example where impellor materials are being remanufactured into sampling blocks. The corrosion resistant qualities of the materials remain beyond the life of the impellor and provide appropriate performance for use as sampling blocks. This allows the materials to remain in use beyond the life of the impellor and avoids virgin materials and reduces manufacturing time.

End of Service Life: A damaged fan impellor could no longer be repaired. We manufactured a replacement & used the material for manufacturing other items.

2nd Service Life: Re-manufactured fan impellor materials for instrumentation mounting blocks to be incorporated on new equipment, cut from the EOL impellor, the materials retain the long-life qualities of fibreglass for a second application.

Reuse of Manufacturing ‘Waste’

Targeting manufacturing offcuts or excess components that are ‘as new’ materials can reduce raw materials use. Retrieved from manufacturing process waste these items can be kept for reuse to save materials and time. The hand lay up process used in our FRP manufacturing processes lends itself to reuse of offcuts due to the ability to layer and reuse compatible components. The key challenge for this is efficient storage and inventory system so that those making new items can quickly assess if a reuse option is in stock & have confidence in the appropriate application conditions. For Armatec this is a work in progress as we trial different ways of organising to find the right level of controls and documentation to support efficiency in this area. Reuse of manufacturing offcuts therefore enables; diverting of manufacturing waste from landfill, reduction of raw materials use & saving fabrication time in the next job.

Reuse of Pipe Offcuts. Armatec holds a selection of manufacturing offcuts for reuse in making other components.

Reuse by Staff for Personal Projects:

Making items available to staff means they can reuse of the materials strength & shape of equipment. In Armatec’s case this involves tanks, moulds, pipes or other FRP components. The equipment is reused in different applications than originally designed for, i.e. farm or home building projects. Opportunities to reuse otherwise waste items by our staff and community members can support keeping the value of materials in use. Storage is always a challenge, so when something must go, reuse by staff presents a business solution. This helps our staff and community by providing free materials to support their projects, prevents waste to landfill and the purchasing of virgin materials.

Armatec staff signal interest in reusing waste items for personal projects.

Garden planters created by reusing the shape of a defect Green Dome by Armatec staff members.

Leveraging People with Manufacturing Knowledge:

Developing team & organisational knowledge for finding reuse & re-manufacturing opportunities is an important business priority to enable reuse into the future.

At Armatec our team aims to use our team knowledge to facilitate reuse of equipment either directly or with modifications to fit a new service.

Therefore, it is critical to ensure these skills, equipment & process knowledge are planned & budgeted for, and cross team collaboration opportunities are stimulated. This can be a challenge to historical team structure, responsibilities & tasks; but starting new types of conversations & opportunities for review has proven valuable to deepening our overall team knowledge. It has proved especially important in succession planning as our most experienced team members head to retirement.

As our team is offering a wide range of services; equipment design, fabrication, testing, installation, commissioning, optimisation, repair and maintenance, they are an active and key piece to enabling reuse & re-manufacturing opportunities to be realised. Team skills, organisational knowledge and equipment records assist us to participate in a circular economy. Armatec’s policy is to support the skill sets required to ensure we have the capability to serve our customers and enable longer service life of our equipment, enable reuse options & continually improve designs.

Providing Local Support for Equipment Maintenance, Reuse & Improvement

Providing inspection, maintenance and repair services gives the opportunity for increased maintenance, repair and continual improvements in design which can be applied to increase the reuse of equipment.

This practical opportunity for design engineers & fabricators to visit, repair and optimise equipment is a valuable feedback loop for increase operational knowledge & to generate new ideas for equipment design. Insights gained provides a variety of improvement ideas; from personnel access & communication supports with operators, to parts availability and streamlining cleaning and maintenance processes. We recognise that historically our repair, maintenance and reuse services has not been as well spotlighted as it could be. While these services have always been provided due to FRP materials being readily repairable and modifiable, we have focused new solutions in marketing. Ensuring our customers are aware of our ongoing commitment to supporting repair, maintenance and reuse is now an active focus. We are continuing to develop our product stewardship processes while solving our customer’s problems and supporting extension of equipment life.

Assessing Equipment for Reuse:

Performing assessments of equipment, by chemical engineers & expert fibreglass fabricators provides a baseline assessment for the status of equipment.

This assessment can be used to identify any repairs required at shutdowns or as part of other routine maintenance to ensure the longest service life is achieved. Assessment skill, provided by our chemical engineers & experienced senior fabricators, is needed to determine the viability for equipment to be reused. For FRP, several tests including barcol hardness, ultrasonic thickness testing, visual checks and surface inspections are used. If required Armatec can do core samples and verify thicknesses & burn-out tests to confirm the laminate sequence of FRP equipment. Laminate adhesion tests are used to confirm that repair laminate will bond sufficiently for reuse.

In our experience we have found that most of the time, damaged fibreglass equipment (FRP) can be repaired and/or strengthened. However, there are some chemicals that do cause a problem with the main one being hydrochloric acid as the acid permeates the laminate and then we cannot get a good bond for repairs. This is an example of where the Armatec team uses process & chemical engineering knowledge to support reuse of equipment.

Increasing Customer & Sector Connections:

Working in collaboration with customers, suppliers and other organisations is critical for reuse to enable the transformation to a circular, low emissions and just sustainable economy.

Adjusting business processes and systems to facilitate and enable reuse of industrial equipment is well underway in NZ and will be accelerated by increased participation from all businesses. Some examples of active NZ reuse platforms are CivilShare (NZ trading of used or excess construction materials & equipment), Mutu (providing circular solutions for asset management) and the directory Reuse - SBN (sustainable.org.nz).

We have found there are many opportunities to start the conversation about reuse opportunities. Getting started can be by way of attending webinars or trainings, doing small trial projects, sharing progress, reaching out to suppliers & customers (particularly those tasked with addressing sustainability in their organisation) and contributing to industry associations.

Sharing Progress

Sharing & celebrating even the small wins as we progress is important to build momentum, team awareness and stimulate new ideas & improvement opportunities.

Business requires that we align with our customers and signal changing expectations & needs to suppliers. Internally we must ensure to communicate changes positively & proactively with our teams to avoid frustrations. Our people design, build, install, commission and maintain our products, they are invested & critical to their success. We aim to share the stories of reuse and waste prevention verbally within meetings, visually in posters and reports. This can involve internal process improvements, sector wide projects, supplier lead initiatives or customer priorities. We would love to see more sharing within our customer and supplier networks and have also taken the approach to use advert space to prompt wider discussion about FRP industrial equipment reuse.

Some examples of recent communications:

Customer Connections

An internal poster celebrating the connection of 2 customers to prevent waste.

Supplier Improvements

Internal poster celebrating working with supplier to reuse packaging.

Manufacturing Process Improvements

This is an example of an improvement project following a waste audit. The waste audit results showed the large volume of cardboard being used for mixing small amounts of bog & other products. While the cardboard was previously used packaging, our use of it for bog then removed it from being able to be recycled as it was contaminated. We have worked to create these reusable boards that are made from recycled HDPV and the supplier has agreed to recycle the boards end of life.

Internal poster to promote the adoption of new reusable bog board to replace single use cardboard.

Sector Contributions

Contributing to sector associations, community & industry research projects and presenting examples of the reuse story & the challenges on the sustainability journey can help others to get started or build momentum for increased reuse.

An example of the approach we have taken to contributing to our sector is through leading a sustainability project for our industry association, Composites Association of New Zealand (CANZ). We support CANZ in the development of national composites reuse & recycling solutions providing resource and skills to benefit our whole sector. For example, Reuse is a key aspect within the developed Composites Design for the Environment Framework, which aims to provide alignment from concept & design through to end user and end of life, as we all make decisions to navigate towards a circular economy. The more we can all engage in the Systems Thinking and Strategy & Comms strands of this framework, it will lead to further unlocking of reuse potential in NZ.

Read more about the framework developed with ThinkStep-ANZ here: Composites Design for the Environment Framework | Composites Association of New Zealand

Advertising to Prompt Conversations

We are currently exploring using advert space in a sector magazine to invite discussion on how reuse of equipment can be stimulated in industry. We have noted the discussion of waste has not historically been a priority, with advertising often focusing on the latest new product or materials innovation. By taking up advertising space to prompt discussion on reuse we hope to reach more people. Ultimately we aim to stimulate reuse discussions everywhere!

Advert placed in Waste Journal May 2024.

Let’s Chat!

Maintaining contact with those who we have supplied equipment to is an obvious advantage in the circular economy.

We seek to encourage the resale or facilitate the repurchase of our equipment so that it can be used again in another industrial service. Armatec is keen to hear from any past customers or current owners of the equipment we have supplied in the past 40+ years of service to NZ. We are happy to discuss the status of this equipment or any scrap yarded items that may have potential reuse in future projects. Working together will enable us all to benefit towards reducing waste and emissions within a circular economy of the future.

Contact us: enquiries@armatec.co.nz

Our why:

As part of our mission, Armatec is committed to product stewardship and addressing the legacy of waste from the past as we transform our industry towards a circular economy.

“Working with Industry & Local Authorities to Reduce Emissions to the Environment” Armatec Mission

We aim to increase our use of recovered and recycled materials towards our goal of achieving 30% recycled (or reused) materials in all new builds. We aspire to continue to provide examples & leadership for industry reducing emissions and be actively working together with customer’s & supplier’s for innovative solutions. We would love to hear from anyone interested in collaborating for further improvements in all aspects of this challenge!

Read more about our sustainability journey here: Armatec Sustainability Program — Armatec Environmental Ltd