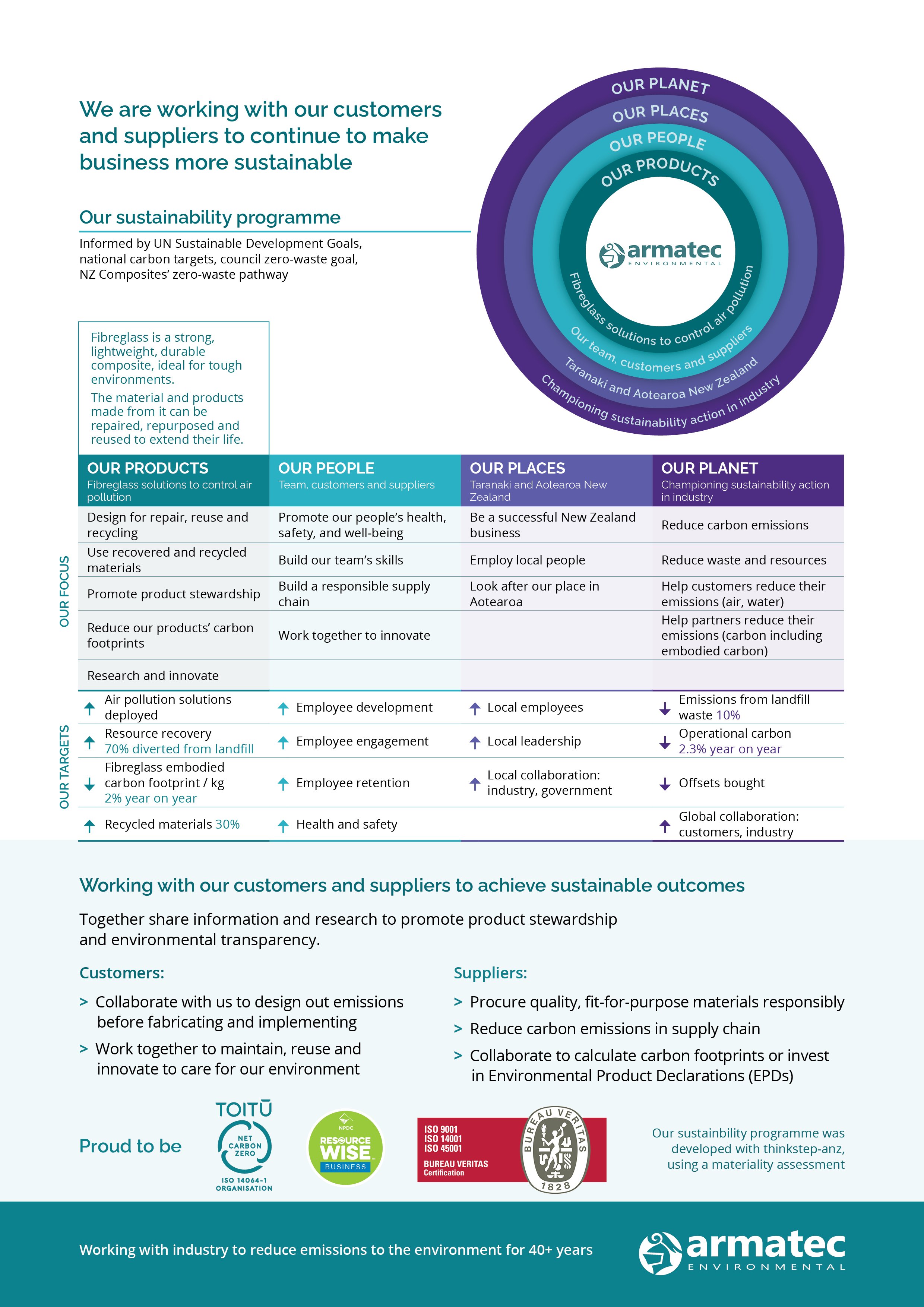

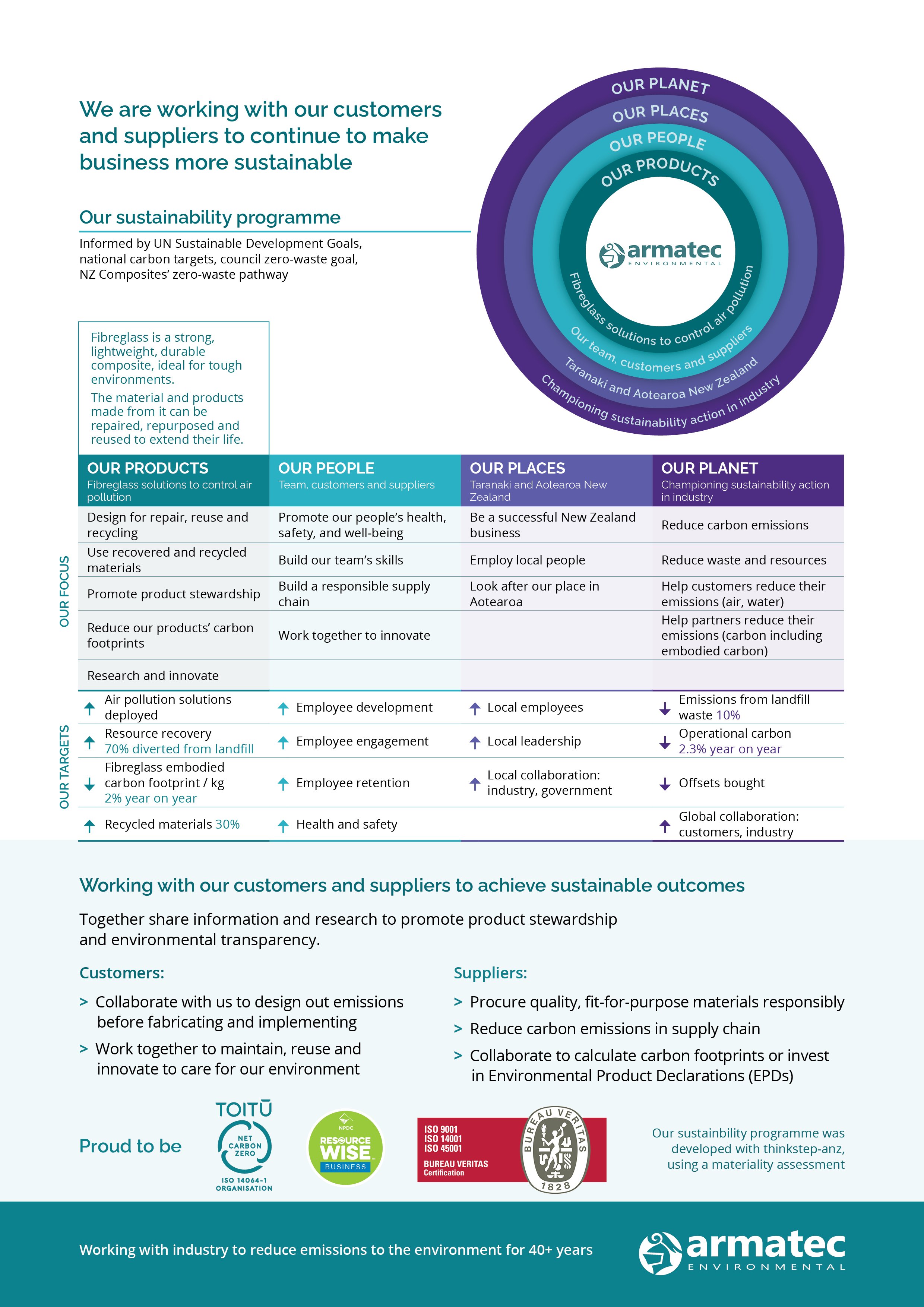

Armatec Sustainability Program

This page describes the focus and targets within our integrated systems that work together to provide our sustainability program framework.

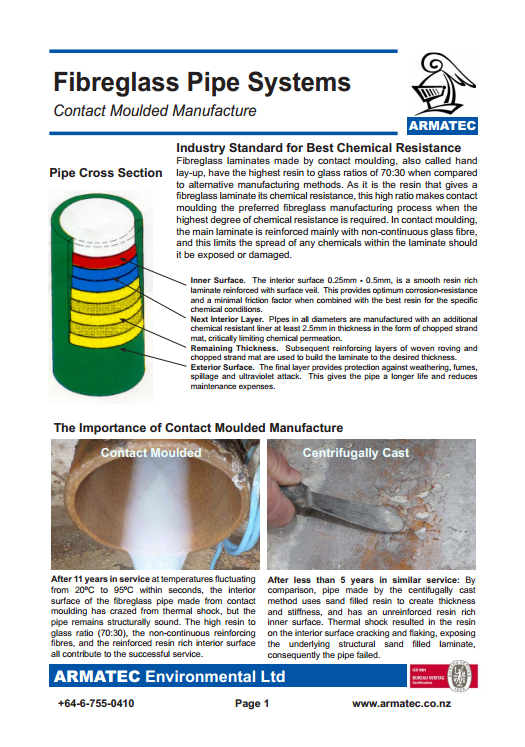

Armatec Fibreglass Pipe Systems

1985: Hydrogen Sulphide Odour Control at Pelt Processing Plant. Chemical scrubber removes over 97% of hydrogen sulphide

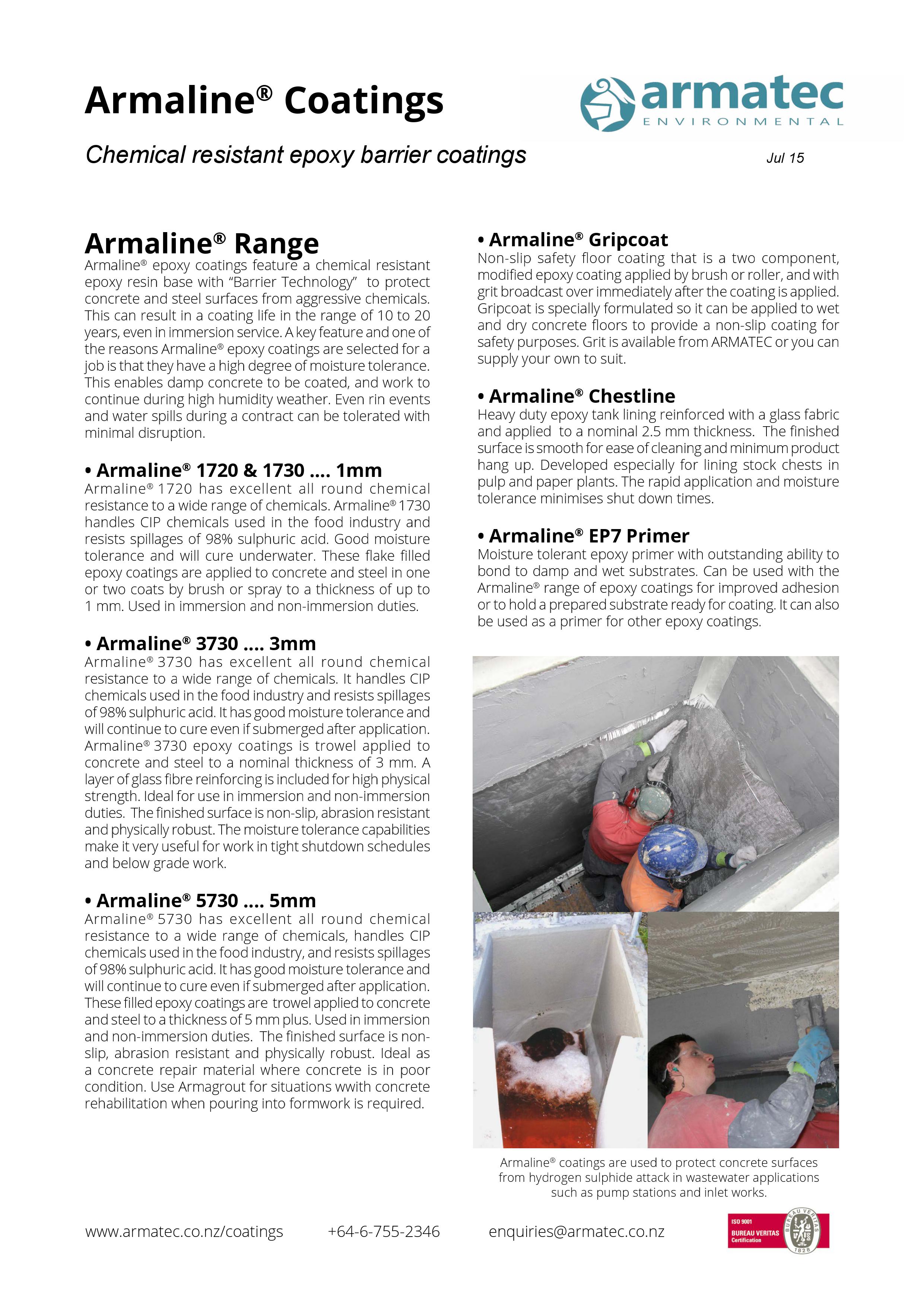

1989: Engineered Approach to Coatings & Linings. The keys to ensuring a successful coating installation

1994: Odour Control at Food Plant. Over 20 streams of up to 75,000 odour units are successfully treated in a venturi scrubber, and achieve a stack outlet odour concentration of 440 odour units

1998: Health & Safety in the FRP Industry. The issues, and how to test and interpret results from workers exposed to styrene

1999: Coatings Permeability Research with EIS. Electrochemical Impedance Spectroscopy is a useful tool in assessing the permeability of a coating.

2006: Styrene and Worker Protection in the Composites Industry. Fibreglass workers are exposed to styrene for long periods.

2006: Phosphorus and Algae Removed from Waihi Facultative Pond Discharge. Outlet concentrations of total P < 0.1mg/1 and SS < 10mg/l achieved.

2007: Biological Scrubber for Hydrogen Sulphide Removal. A New Zealand first treating air stream with up to 300ppm of hydrogen sulphide.

2010: Odour Control for Pump Stations. Results of work done controlling odours at two pump stations in New Zealand.

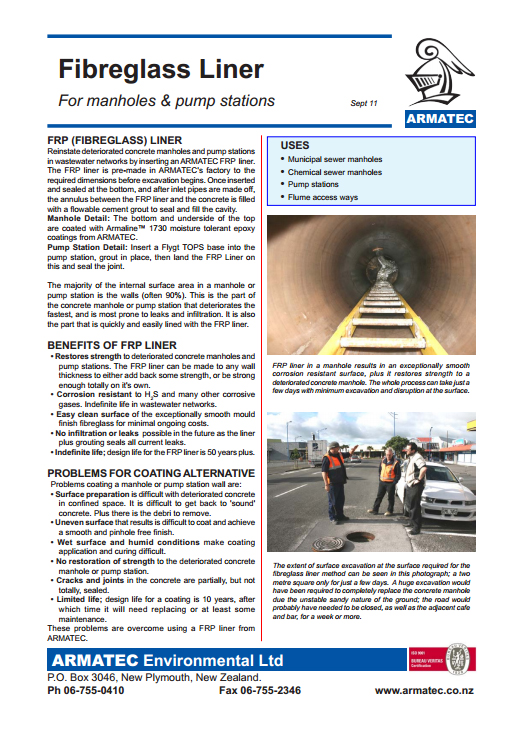

2011: Lessons Learned Rehabilitating Manholes & Pump Stations with Fibreglass Liners. Fibreglass Liners have a lot of advantages, but there are some pitfalls. These are some of the lessons leaned

2011: Fibreglass Pump Stations: 10 Years Experience in New Zealand. Presented at NZ Water Conference, Rotorua November 2011.

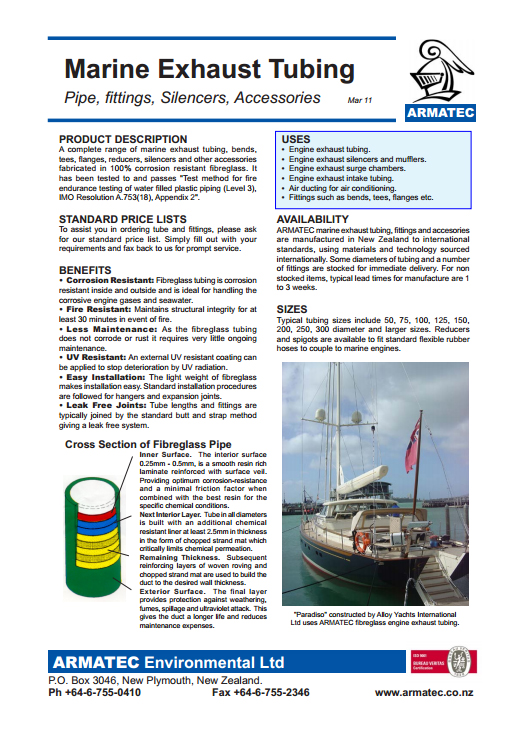

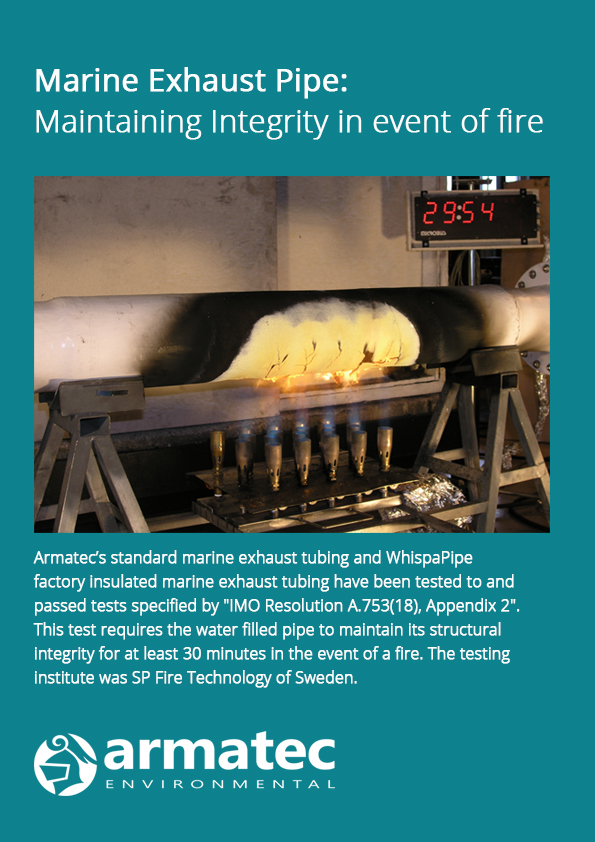

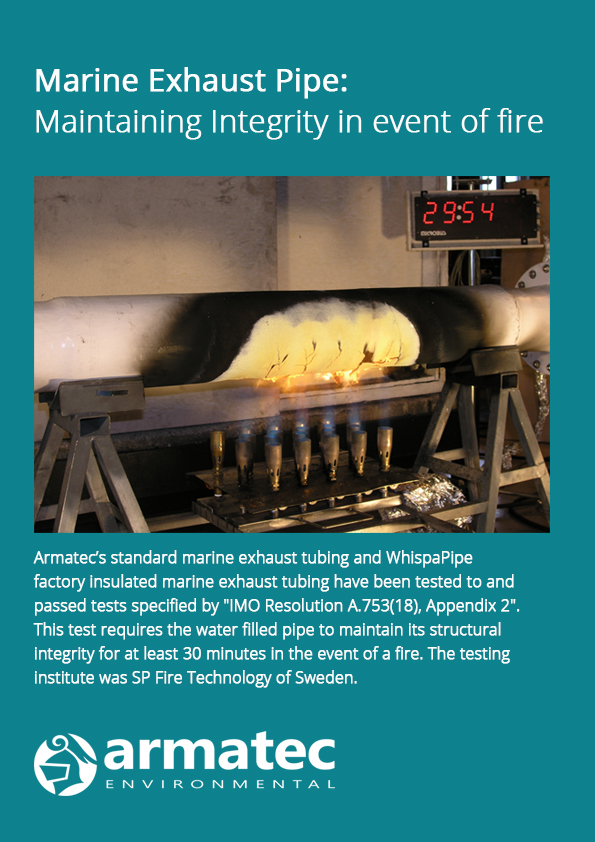

Marine Exhaust Pipe: Maintaining Integrity in event of fire

Armatec's standard marine exhaust tubing and WhispaPipe factory insulated marine exhaust tubing have been tested to and passed tests specified by "IMO Resolution A.753(18), Appendix 2". This test requires the water filled pipe to maintain its structural integrity for at least 30 minutes in the event of a fire. The testing institute was SP Fire Technology of Sweden.